SKMM-10

Hydraulic/pneumatic pressurization skid. Controlled by electrical pushbutton on a graphical synoptic panel or manual needle valves (GAS). Every process element is controlled directly by the operator; main safety garrison for wrong maneuvers has been included.

This make the SKID very flexible to any testing procedure. Leak could be measured (option) by electronic bubbles counter, high accuracy water column (API) , turbine flow meter and mass flow meter (FCI 70-2).

Vacuum pump could be installed (option) to assure the absence of air inside valve’s body before filling it with water; in order to reduce test time and increase operator’s safety.

All wet process components are stainless steel made and dimensioned for a working pressure of 700bar (1200/2100/4000bar as option).

*Standard version is described. Test benches can be customized in any technical aspect in accord to client peferences.(Patent Pending)

- Max working pressure H2O700 / 1200 / 2100 / 4000 bar

- N2700 / 1050 bar

- Air200 / 450 bar

- Filling flow H2O10L/min ( 10L Internal TANK Included)

- DBB test opt.Included

- GAS Booster optAvailable

- CAVITY testAvailable

- ATEX certification opt.Available

- Process styleBidirectional

- HP Fluid allowedWater, Water & oil mixture. Glicole, Ethanol / Methanol (Atex).

- Control systemManual needle valve

- Pressure measureAnalog gauge / digital

- Ref. StandardAPI / DIN / BS / FCI

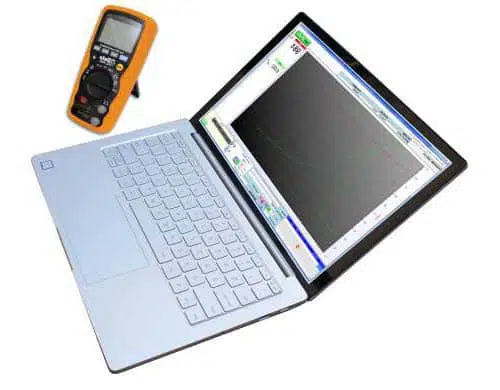

- Serial InterfaceRS-485 MODBUS PROTOCOL

- Certification softwareOption TestREC

- Process ConnectionsBSPP ½ "-F / HP 1/4"-F

- Service air supply7bar @ 2000 L/min Other available on request

- Dimensions (mech)700(L) x 300(D) x 350(H)