BV-PMC/650

MOBILE BRIDGE. PROPORTIONAL PRESS CLAMPING

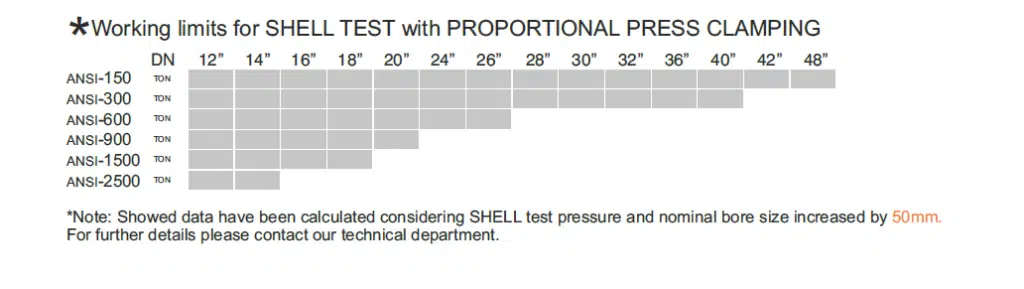

Vertical test rig with controlled pressing clamp; press force is automatically controlled according to the water pressure inside valves, and the result load is reduced to minimal terms.

The mobile upper side bridge allows vertical loading of valves and the possibility to have double working stands; while the first is working, the second could be prepared for the next valves.

In the basement there is a water vessel and an external water vessel could be added as option.

The use of an open castle as an upper side reaction structure allows the user to make visual inspections of valve seats during the test.

The rig has an armored glass protection on 3 sides according EN1063.

The front side can be closed by a mobile horizontal sliding gate (optional).

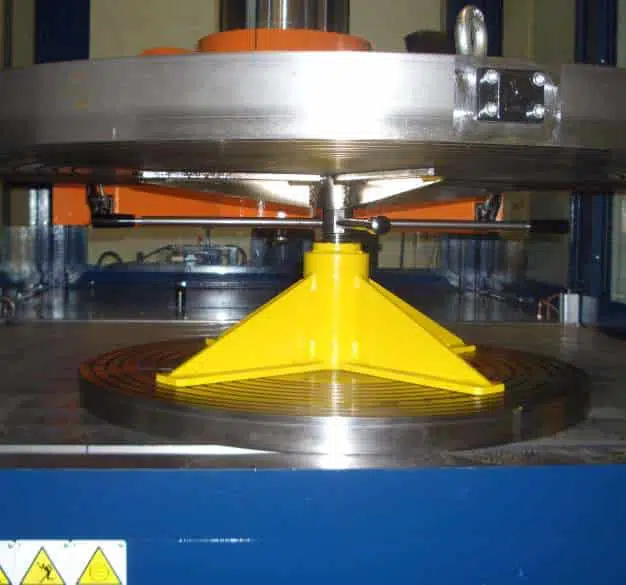

Upper side crociera is equipped with a fast connection (photo 2) for sealing plateau, and a mounting tool is included as well (photo 1).

The rig is controlled by a SKA-100 pressurization skid; to have more information about it please consult dedicate technical data sheets.

The rig could be completed with several options and accessories, please contact our sales office to have more information.

*Standard version is described. Test benches can be customized in any technical aspect in accord to client peferences.(Patent Pending)

- Reaction force (See working limits table)650TON (10% minimum press clamping) (See working limits table)

- Working stands1(2 on request)

- Allowed sizesDN700/DN2000PN16/PN64

- Length max1250mm

- Length min200mm

- Columns inner distance1600mm

- Loading height1000mm

- Bridge stroke1300mm

- Basement water vessel220 Liters (only for spilled water not for storage)

- Terminations allowedRF, RJ

- Clamping styleType 1 - Proportional press Clamping

- Clamping force controlAutomatic within 10..100% interval, proportional to hydrostatic pressure inside the valve under test.

- Protection against water jetArmoured glass on 3 side according En1063 + front door on request

- Dimensions2350(L) x 2900(P) x 4240(H)