OUR MISSION

We do trust in test results as key factor for a successful business. Testing products to improve their quality and be protected from any risk doing it.

Think’ PC PROGETTI offers a wide selection of test benches rigorously designed according to the most important international standards and specific custom needs.

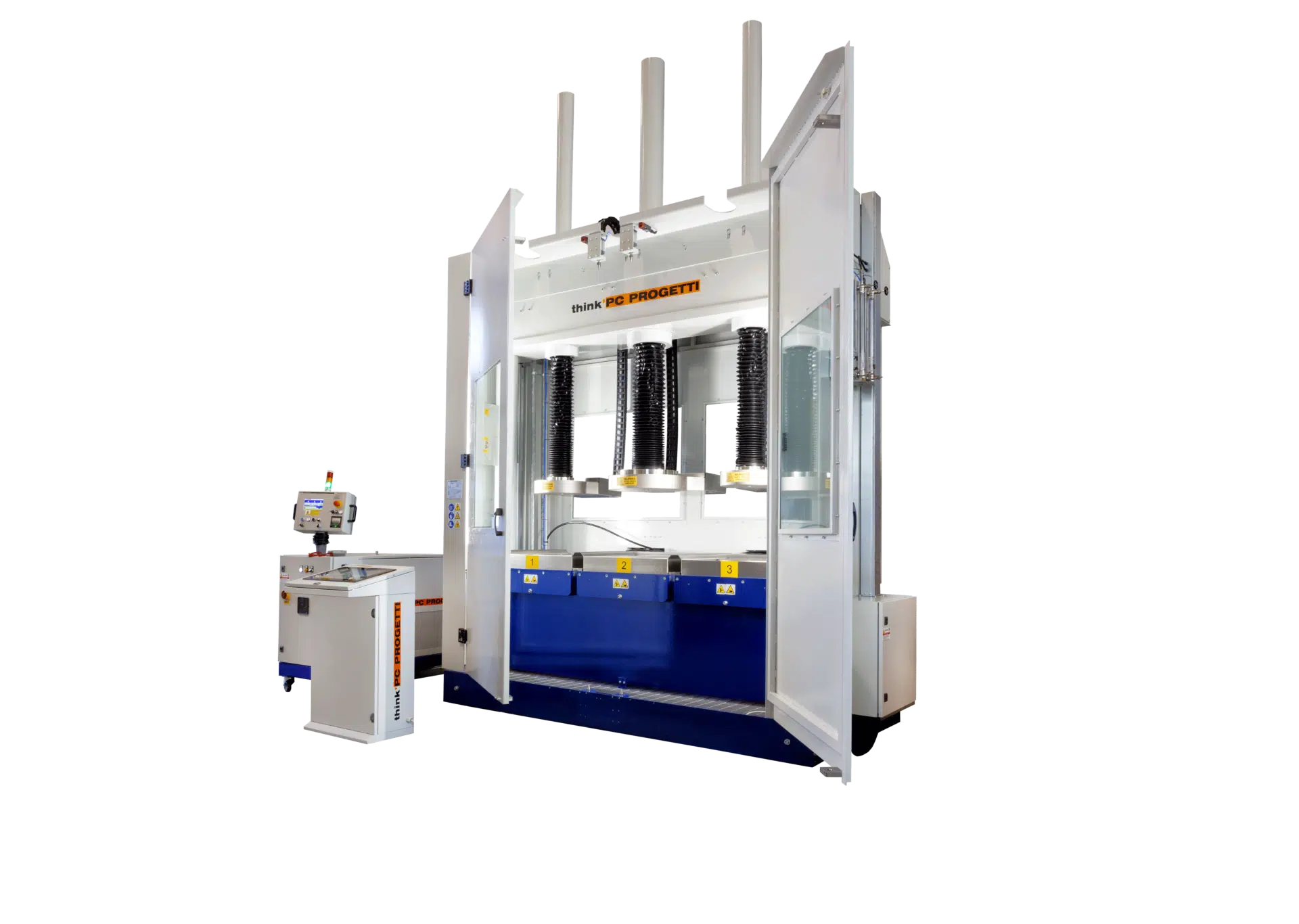

Test benches for valves

Think’ PC PROGETTI provides a complete selection of test benches for valves, from the most common to the most complex realizations, to satisfy any type of customer need. Check out our catalog and find the machines that best suit your test objectives

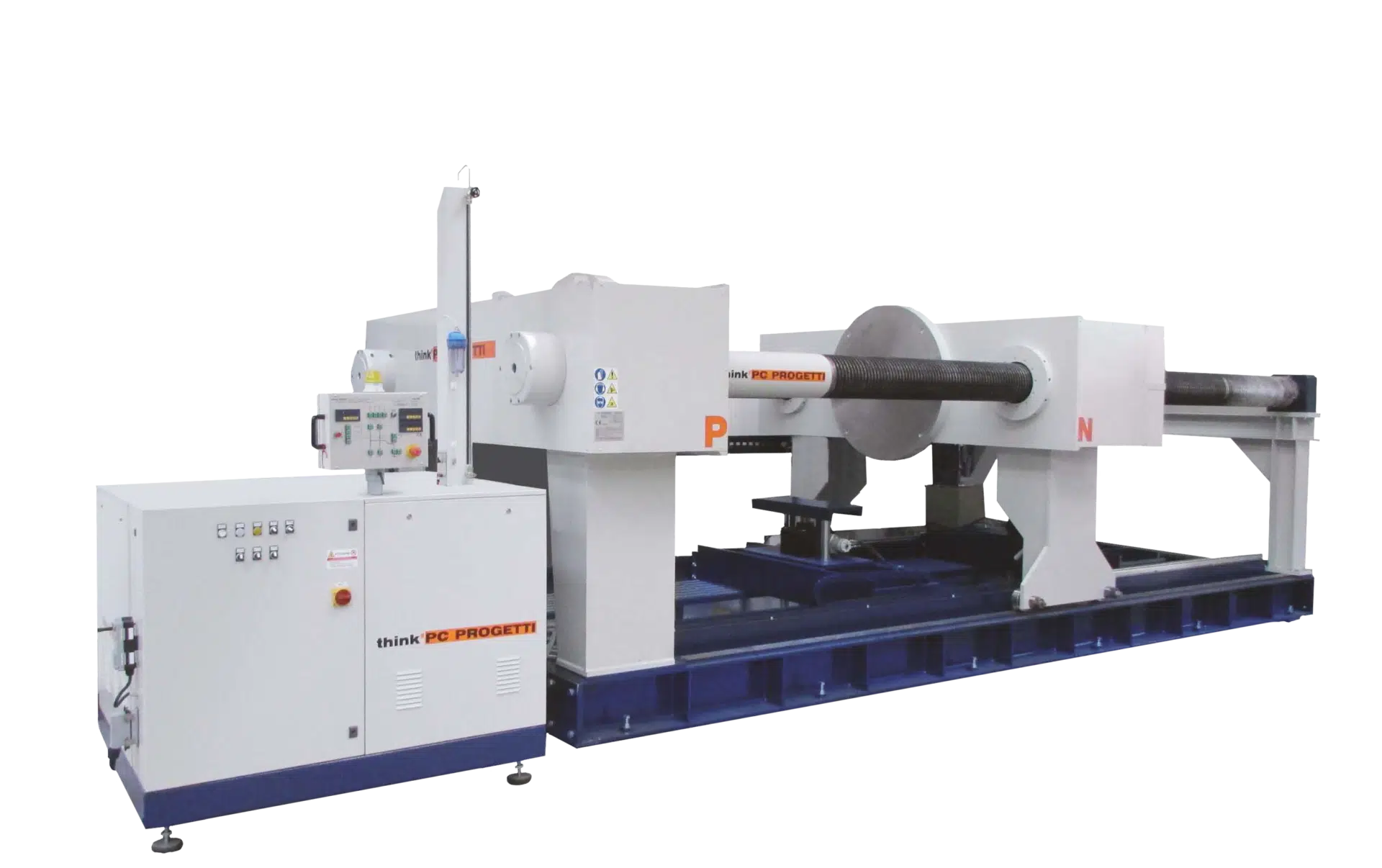

Test benches for pipes

Think ‘PC PROGETTI has produced test benches for pipes up to 12.5 meters in length and 1420 mm in diameter. Look at the selection of the plants built.

Test benches for actuators

Think ‘PC PROGETTI manufactures test benches for actuators up to 400,000 Nm, with specific options of our software TestRec v11.0.0 dedicated to the analysis of test results. Browse the catalogue to view the proposed options.

Featured products

News

Clamping styles

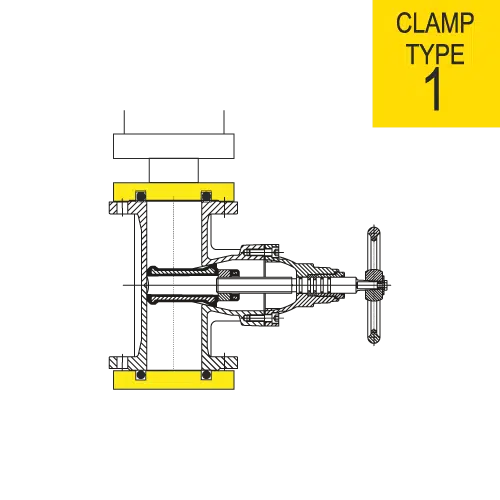

Clamp type 1

Pressing

Proportionally controlled or On/Off switch.

Reaction against water hydrostatic force inside the valve is made by an hydraulic cylinder. It can be controlled by a proportional oil regulation loop, to the effective water pressure inside the valve or simply with a ON/OFF control to the total amount of strength needed.

Proportional press block allows the system to strongly reduce mechanical effort on valve body. Limit of 10% minimum pressing power.

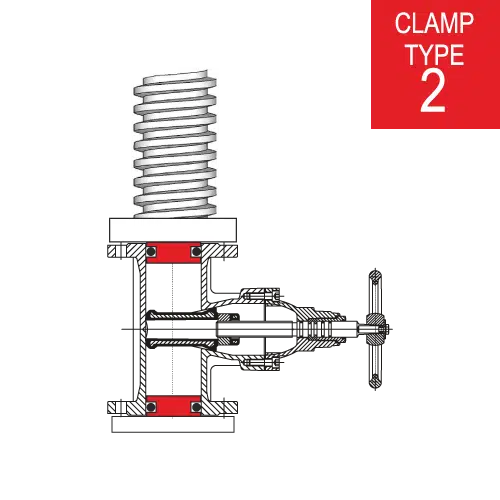

Clamp type 2

Inner radial

No external forces applied on valve body.

The tightness is made by a O-Ring seal that works on the inner side of valve body.

Also called “Bore Plugs” style.

This clamping style allows the valve to expand itself under the pressure test solicitation. This test style suggested by all widespread test standards.

Bore plugs adaptors need a low roughness grade on valve bore, allowing O-Rings to make the tightness.

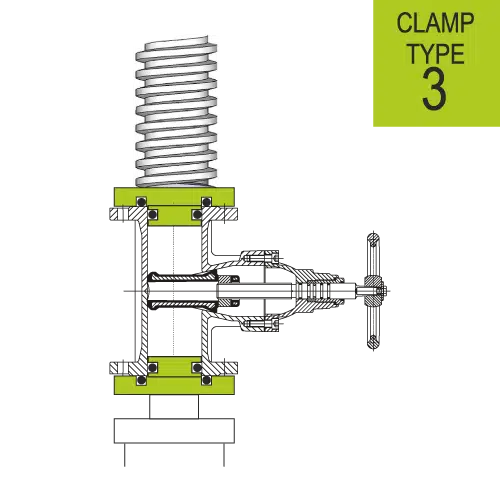

Clamp type 3

Combined

Suitable for all valve termination kinds. It is a combination of style “1% and “2”.

In one test rig there are both clamping possibilities.

Operators can select the best one according to the kind of valve under test.

Limit of 10% minimum pressing clamp.

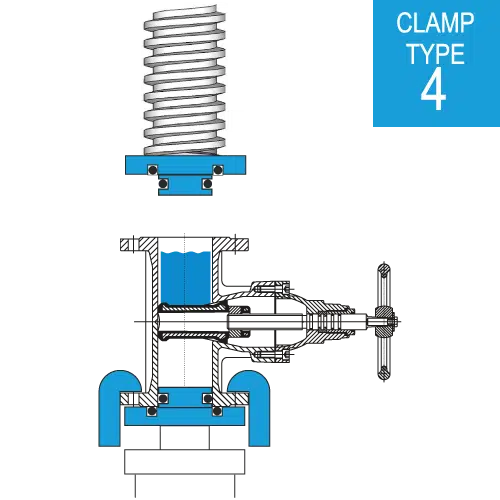

Clamp type 4

Universal

Visual leak test.

It has the same blocking ability of clamping style”3”, plus claws added to one clamping side.

This allows the user to make a visual check of seat leakage, on a flanged valve not machined in the bore.

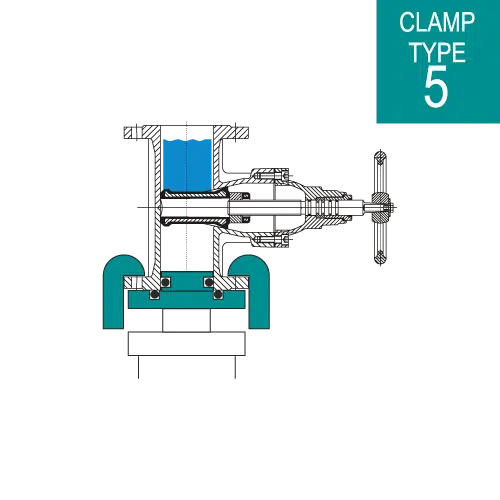

Clamp type 5

Claws only

Visual leak test.

It has the same block ability of tightness type “4”, without an upper side closing device.

This makes it the most suitable clamping style for 90° angle valves or PSV.

It can be used only for flanged valves.

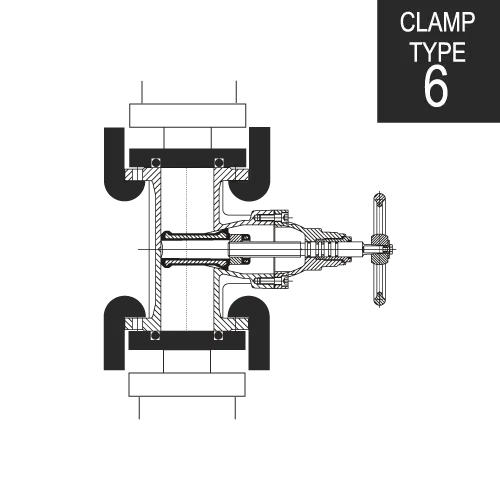

Clamp type 6

Double Claws

Both valve sides are clamped with claws clamping style.

It can be used only for flanged valves.

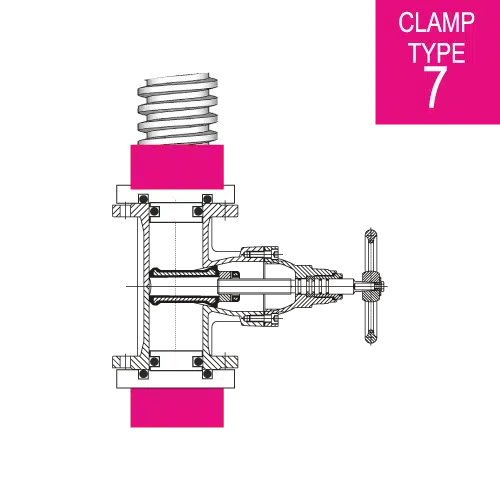

Clamp type 7

P.E.A. Adaptors

Automatic proportional press clamping.

Useful for flange surface with O-Ring seal, developing a natural accurate proportional press clamping applied to a clamping style Nr. 2 test benches or bolts clamping table.

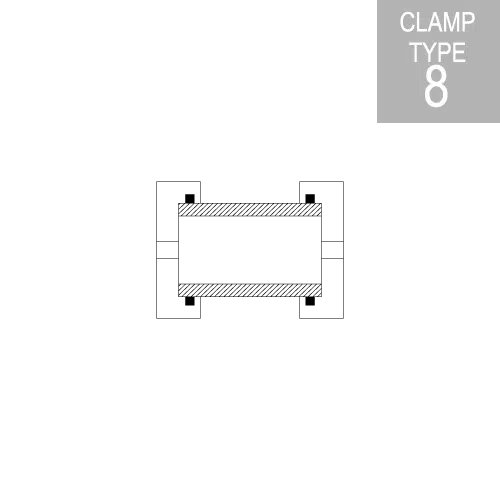

Clamp type 8

Auto-Adaptive seals

Special automatic overpressure adaptive seals able to peform perfect thighness on pipes/pubs not perfectly round, with elliptical deformation up to 2% of nominal diameter. Especially suggested for pipes testing rigs.