BO30-2CV/50P

Horizontal test rig with combined clamping style: inner radial seal and press clamping facilities. The mobile reaction bridge is moved by one screwed columns that assures complete absence of external forces on valve body and an hydraulic cylinder can make press clamping with or without proportional control.

This prerogative makes it compliant to the most widespread international test standards. A spacer of 600 mm is placed on the fixed bridge side to accomodate large actuators. A water vessel is installed in the basement as water reservoir for test procedures. Test process is controlled by electronic PLC & LCD touch screen.

Test data can be printed out on 24cln thermal printer directly in the testing area or it can be downloaded with serial connection (standard) to Windows based PC with TestREC certification software.

*Standard version is described. Test benches can be customized in any technical aspect in accord to client peferences.(Patent Pending)

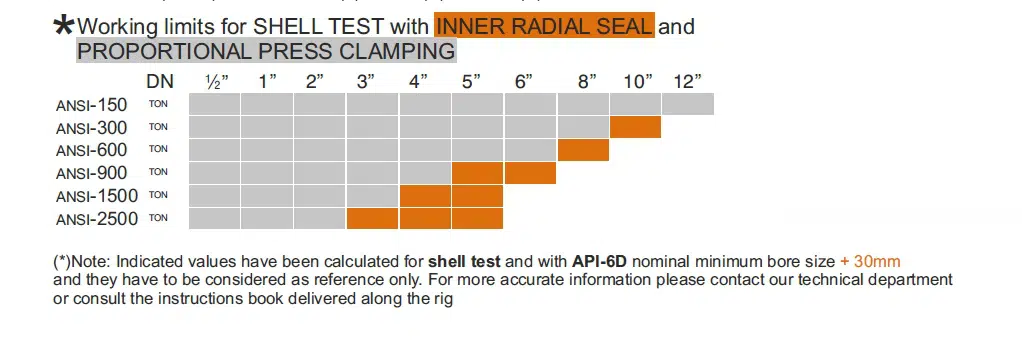

- Reaction force50 TON(10% minimum press clamping) (see working limits table)

- Valve lenght max620 mm

- Valve lenght min0 mm

- Columns inner distance590 mm

- Flow axes height885 mm

- Basement water vessel100 Liters

- Termination allowedRF, RTJ, BW, SW

- Clamping styleType 3 - combined clamping

- Clamping force controlOn/off & proportional (option)

- Reference standardsISO, DIN, API, ANSI, ASTM, FCI, BS (Other on request).

- Filling Flow50 Liter/min

- Vacuum pump36m /h (Option)

- Vacuum pumpStandard flow meterSee table (other flowmeter asset on request)

- Max pressure700 bar (water) - 6 bar (AIR)

- Dimensions (mech)3670(L) x 600(P) x 1700(H)

* Working limits for SHELL TEST with INNER RADIAL SEAL and PROPORTIONAL PRESS CLAMPING